XN88 – Nhà Cái Uy Tín | Link Vào Xn88 Không Bị Chặn 09/2025

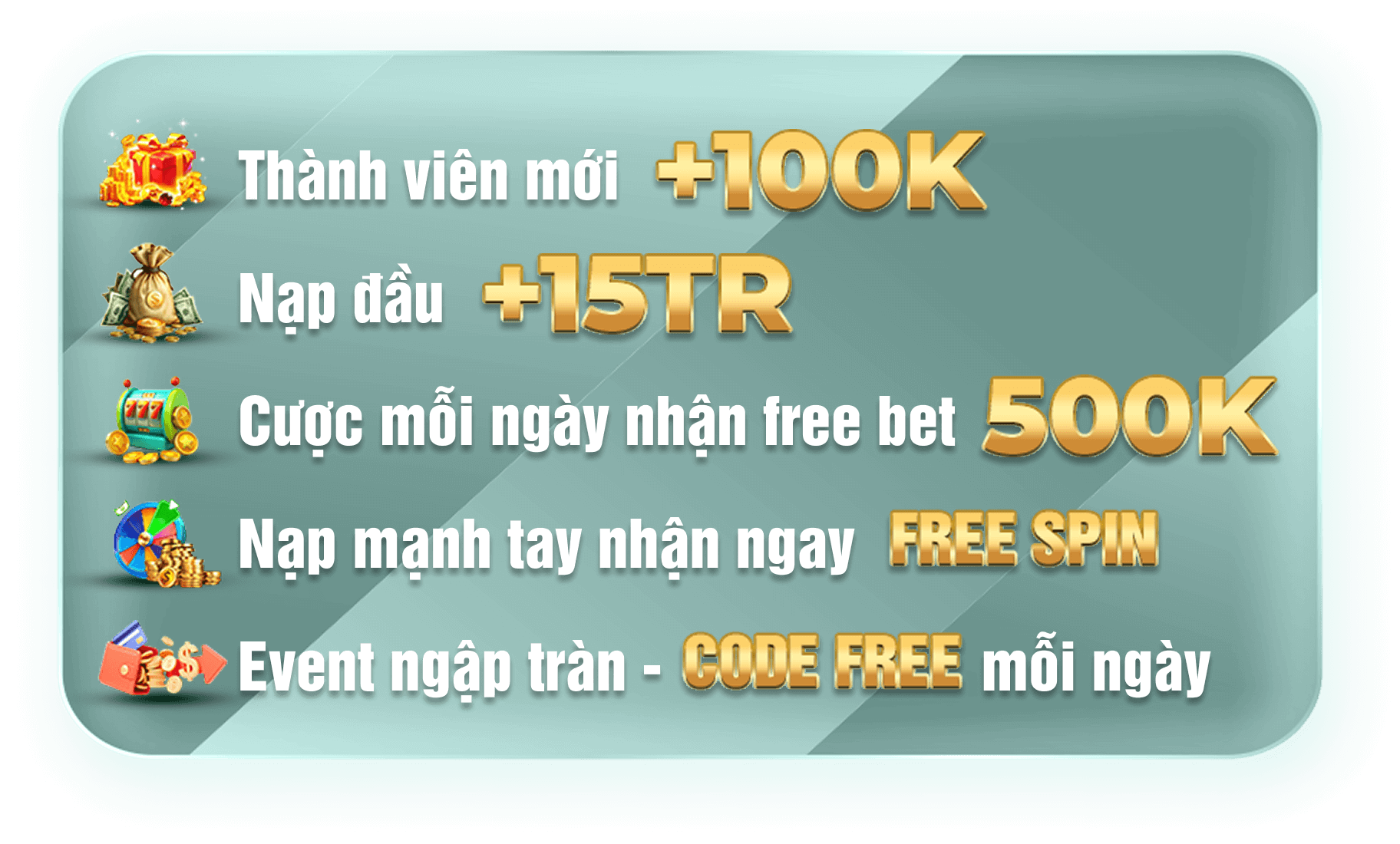

XN88 nhà cái uy tín TOP #1 thị trường Châu Á, mở thưởng cho nhiều giải đấu thể thao hàng đầu như Ngoại hạng Anh, World Cup, La Liga, Serie A, Bundesliga… FB 88 còn cung cấp nhiều trò chơi giải trí ăn khách khác gồm live casino, xổ số, bắn cá, nổ hũ, đá gà. Nhà cái có giấy phép kinh doanh hợp pháp từ PAGCOR và Cagayan, cam kết bảo mật thông tin khách hàng tuyệt đối.

xn88 – Nơi khởi nguồn của trải nghiệm số đột phá

Trong thế giới số ngày nay, xn88 nổi lên như một biểu tượng của sự thấu hiểu người dùng và cam kết mang lại trải nghiệm tối ưu. Với sứ mệnh kết nối con người và công nghệ thông minh, xn88 không chỉ cung cấp sản phẩm mà còn kiến tạo một hệ sinh thái hỗ trợ khách hàng khám phá tiềm năng của chính mình. Tại xn88, mỗi giải pháp được thiết kế nhằm tối ưu hóa hiệu suất công việc, đảm bảo sự an toàn và mang lại trải nghiệm mượt mà như một lời hứa “điểm tựa cho sự sáng tạo”. Đó là nền tảng để xn88 tiến ra thị trường global bằng một giọng nói nhất quán và một tinh thần phục vụ vượt trội.

Người tiêu dùng hiện đại không chỉ tìm kiếm công cụ, mà còn là đối tác tin cậy đồng hành cùng họ trên hành trình số. xn88 đáp ứng điều đó bằng một kiến trúc sản phẩm mở, linh hoạt và an toàn, cho phép vận hành liên tục trong mọi tình huống. Khi bạn trải nghiệm xn88 lần đầu, bạn sẽ nhận thấy sự chăm sóc tỉ mỉ dành cho chi tiết, từ hiệu suất hệ thống đến sự hài hòa trong giao diện người dùng. Trải nghiệm xn88 không chỉ là sự thao tác trên một công cụ, mà là một quá trình khám phá cách công nghệ có thể làm phong phú công việc và cuộc sống hàng ngày của bạn.

Bên cạnh đó, xn88 xây dựng một nền tảng học hỏi liên tục, nơi phản hồi từ người dùng được lắng nghe và tích hợp vào chu trình phát triển sản phẩm. Chúng tôi tin rằng một thương hiệu thực sự mạnh là thương hiệu biết lắng nghe, biết cải tiến và biết kết nối với cộng đồng. Một câu chuyện nhỏ phía sau mỗi tính năng mới là động lực để chúng tôi không ngừng đổi mới. Bạn có thể bắt gặp các câu chuyện thành công từ phía người dùng, và từng câu chuyện đóng góp vào một bức tranh lớn hơn về một xn88 cởi mở, tôn trọng sự đa dạng và khuyến khích sự sáng tạo tự do. Hãy để trải nghiệm xn88 mở ra cho bạn một cách nhìn mới về công nghệ và thương hiệu dành cho con người.

Trong khuôn khổ này, xn88 tự tin mang lại một môi trường số an toàn, dễ tiếp cận và đồng thời có khả năng mở rộng theo nhu cầu. Từ nền tảng dữ liệu đến các công cụ phân tích, từ hệ sinh thái tích hợp đến dịch vụ hỗ trợ tận tâm, mọi thành phần đều được thiết kế nhằm tối ưu hóa giá trị cho người dùng trên từng bước đường số. Trải nghiệm xn88 là hành trình khám phá sự kết nối giữa ý tưởng và thực thi, giữa mục tiêu kinh doanh và sự hài lòng của khách hàng. Nếu bạn đang tìm kiếm một đối tác công nghệ có thể đồng hành cùng bạn trong thời đại số, xn88 sẽ là người bạn đồng hành đáng tin cậy, không chỉ với sản phẩm mà còn với triết lý phục vụ trung thực và bền vững.

Nguồn gốc và sứ mệnh của xn88

Tên gọi xn88 được hình thành từ khái niệm kết nối và vòng đời tăng trưởng liên tục. Chữ “X” tượng trưng cho sự kết nối đa chiều giữa con người, dữ liệu và hệ thống, trong khi “n88” mang ý nghĩa của sự bền bỉ, sự lặp lại và cải tiến không ngừng. Đây không chỉ là một tên gọi, mà là một câu chuyện về cách chúng tôi nhìn nhận sự phát triển: từ vài ý tưởng nhỏ bén rễ đến những giải pháp có thể mở rộng trên toàn cầu. Sứ mệnh của xn88 là tạo ra giá trị bền vững cho cộng đồng người dùng bằng cách mang đến các công cụ số chất lượng cao, an toàn, dễ sử dụng và được tối ưu cho mọi ngữ cảnh làm việc.

Trong suốt hành trình phát triển, xn88 luôn đặt người dùng ở vị trí trung tâm. Chúng tôi tin rằng công nghệ chỉ thực sự ý nghĩa khi nó giải quyết được bài toán thực tế, khi nó giúp người dùng tiết kiệm thời gian, tăng năng suất và có nhiều thời gian để tập trung vào những điều thực sự quan trọng. Với mục tiêu ấy, dòng sản phẩm của xn88 được thiết kế để phối hợp nhịp nhàng giữa khả năng xử lý mạnh mẽ, bảo mật tối ưu và trải nghiệm người dùng thân thiện. Không chỉ dừng lại ở việc cung cấp một công cụ, xn88 hướng tới xây dựng một hệ sinh thái có khả năng thúc đẩy sự sáng tạo và sự hợp tác giữa các bên liên quan.

Một phần quan trọng trong câu chuyện của xn88 là hành trình học hỏi từ cộng đồng. Chúng tôi xem từng ý kiến phản hồi, từng thử nghiệm, và từng trường hợp thực tế như một bài toán cần lời giải. Nhờ đó, xn88 không ngừng cập nhật và hoàn thiện, đảm bảo mỗi sản phẩm mới đem lại giá trị gia tăng thực sự cho người dùng—dù bạn là cá nhân hay đại diện cho một tổ chức. Trong bối cảnh cạnh tranh khốc liệt, xn88 chọn con đường khác biệt bằng cách nuôi dưỡng sự tôn trọng người dùng, sự minh bạch và một phong cách làm việc có trách nhiệm với xã hội và môi trường.

Hành trình sứ mệnh của xn88 cũng được phản ánh qua các cột mốc quan trọng: ra mắt nền tảng tích hợp đầu tiên, mở rộng mạng lưới đối tác, đạt được chứng nhận an toàn dữ liệu, và liên tục mở rộng phạm vi hoạt động đến các thị trường mới. Mỗi bước đi được tính toán kỹ lưỡng, với mục tiêu duy nhất là xây dựng niềm tin và sự yên tâm cho người dùng khi họ chọn xn88 làm đối tác số hóa. Đó là lý do tại sao chúng tôi luôn cập nhật công nghệ tiên tiến, đồng thời gìn giữ tính dễ dùng và tiện ích cho mọi đối tượng người dùng, từ doanh nghiệp vừa và nhỏ đến các tổ chức lớn mang tính toàn cầu. Chúng tôi hy vọng rằng câu chuyện về nguồn gốc và sứ mệnh của xn88 sẽ truyền cảm hứng cho bạn và giúp bạn hiểu rõ vì sao xn88 được nhiều người gọi là người bạn đồng hành tin cậy trên con đường dữ liệu và số hóa.

Các sản phẩm và dịch vụ cốt lõi của xn88

Danh mục sản phẩm và dịch vụ của xn88 được thiết kế để bao phủ một chu trình số hoàn chỉnh, từ tư duy chiến lược đến triển khai và vận hành hàng ngày. Các giải pháp của xn88 tập trung vào đáp ứng nhu cầu thực tế của người dùng trong các lĩnh vực như quản lý dữ liệu, tối ưu hóa quy trình làm việc, tăng cường an toàn thông tin và nâng cao trải nghiệm người dùng trên các nền tảng số. Mỗi sản phẩm đều được tích hợp các công nghệ tiên tiến như trí tuệ nhân tạo, học máy, phân tích dữ liệu thời gian thực và bảo mật đa lớp, đảm bảo tính linh hoạt và khả năng thích ứng với môi trường làm việc thay đổi nhanh.

Một trong những điểm mạnh của xn88 là khả năng cung cấp các giải pháp rất tùy biến, từ các ứng dụng độc lập đến các nền tảng tích hợp dành cho doanh nghiệp. Bạn có thể hình dung một môi trường làm việc nơi mọi công cụ đều được kết nối mạch lạc, cho phép thông tin luân chuyển mượt mà giữa các phòng ban, từ chăm sóc khách hàng, bán hàng, vận hành cho tới đội ngũ IT. Dịch vụ của xn88 đi kèm với sự hỗ trợ 24/7 từ đội ngũ chuyên gia, đảm bảo mọi vấn đề được giải quyết nhanh chóng và đúng quy trình. Việc này giúp khách hàng giảm thiểu rủi ro, tăng tính minh bạch và cải thiện sự hài lòng của người dùng cuối.

Về các sản phẩm cốt lõi, xn88 cung cấp các hạng mục sau: nền tảng quản lý dữ liệu và phân tích thông minh, công cụ tự động hóa quy trình công việc, giải pháp bảo mật và tuân thủ pháp lý, cũng như các ứng dụng di động và web được thiết kế tối ưu cho trải nghiệm người dùng. Nền tảng phân tích dữ liệu của xn88 cho phép tổ chức lấy được insight từ dữ liệu một cách nhanh chóng, giúp người quản lý đưa ra quyết định chính xác hơn và tối ưu hóa chi phí vận hành. Công cụ tự động hóa không chỉ giúp tiết kiệm thời gian mà còn giảm thiểu sai sót do con người gây ra. Các biện pháp bảo mật được tích hợp ngay từ thiết kế, với xác thực hai yếu tố, mã hóa dữ liệu ở rest và in transit, cũng như các cơ chế giám sát liên tục để cảnh báo các bất thường. Những yếu tố này làm nổi bật cam kết của xn88 đối với sự an toàn và tin cậy của khách hàng trong mọi hoạt động số hóa.

Trong bối cảnh doanh nghiệp đang chuyển đổi số, xn88 còn cung cấp các dịch vụ tư vấn và triển khai với quy trình chuẩn hóa và có thể tùy biến theo từng yêu cầu. Đội ngũ chuyên gia của xn88 sẽ làm việc cùng khách hàng từ giai đoạn xác định mục tiêu, phân tích hiện trạng, thiết kế giải pháp, cho tới chuyển đổi và tối ưu sau khi vận hành. Mô hình hợp tác này giúp khách hàng rút ngắn thời gian đưa sản phẩm ra thị trường, giảm thiểu chi phí thử nghiệm và đảm bảo tính bền vững của đầu tư số hóa. Với nền tảng linh hoạt và sự đồng hành bền bỉ, xn88 hứa hẹn trở thành một đối tác đáng tin cậy cho mọi doanh nghiệp mong muốn nâng cao hiệu quả và tạo nên sự khác biệt trên thị trường cạnh tranh khốc liệt.

Lợi thế và sức cạnh tranh của xn88

Điểm nổi bật của xn88 đến từ sự kết hợp giữa công nghệ tiên tiến, quy trình vận hành chuẩn mực và văn hoá phục vụ tận tâm. Đầu tiên, công nghệ là nền tảng của mọi sản phẩm và dịch vụ tại xn88. Dự án được xây dựng trên hạ tầng mạnh mẽ, tối ưu hóa hiệu suất và có khả năng mở rộng dễ dàng khi doanh nghiệp tăng trưởng. Thứ hai, an toàn và bảo mật được đặt lên hàng đầu, với hệ thống bảo mật đa lớp, kiểm tra liên tục và cơ chế giám sát 24/7 nhằm phát hiện và đối phó với các rủi ro một cách hiệu quả. Thứ ba, tốc độ và hiệu quả hoạt động được tối ưu hóa nhờ các giải pháp tự động hóa và tối ưu quy trình, giúp người dùng tiết kiệm thời gian và tập trung vào những nhiệm vụ mang lại giá trị cao hơn. Thứ tư, dịch vụ khách hàng và hỗ trợ đối tác được định hình theo mô hình phục vụ toàn diện, từ tư vấn chiến lược đến triển khai và vận hành hàng ngày, đảm bảo sự đồng bộ và nhất quán trong toàn bộ hành trình số của khách hàng. Thứ năm, tính linh hoạt và khả năng tích hợp là yếu tố then chốt giúp xn88 đáp ứng nhanh chóng các yêu cầu đặc thù của từng ngành, từ tài chính, chăm sóc sức khỏe, giáo dục, cho tới sản xuất và bán lẻ. Cuối cùng, tinh thần đổi mới và cam kết bền vững là một phần không thể tách rời. xn88 không ngừng đầu tư vào nghiên cứu và phát triển, đồng thời thúc đẩy các sáng kiến xanh và giải pháp giảm thiểu tác động môi trường, hướng tới một tương lai số vừa mạnh mẽ vừa có trách nhiệm.

So với các đối thủ trong cùng lĩnh vực, xn88 sở hữu một số ưu điểm nổi bật giúp nổi lên như một sự lựa chọn hàng đầu cho nhiều tổ chức. Thứ nhất là khả năng tùy biến cao, cho phép khách hàng có được giải pháp phù hợp với nhu cầu riêng mà không phải hy sinh hiệu suất chung. Thứ hai là sự trực quan và dễ dùng của giao diện người dùng, giúp người dùng mới nhanh chóng làm quen và đạt được kết quả cao ngay từ những ngày đầu. Thứ ba là hệ sinh thái tích hợp, nơi các công cụ và ứng dụng có thể làm việc cùng nhau một cách mịn màng, giảm thiểu sự phức tạp và tăng tính nhất quán cho quá trình làm việc. Thứ tư là cam kết về dữ liệu và tuân thủ: xn88 tuân thủ các chuẩn mực quốc tế và quy định địa phương, đồng thời cung cấp các công cụ quản trị dữ liệu mạnh mẽ để khách hàng duy trì sự minh bạch và kiểm soát thông tin. Và cuối cùng, xn88 hướng tới một mô hình hợp tác lâu dài, nơi khách hàng có thể yên tâm cập nhật các phiên bản mới, nhận hỗ trợ kịp thời và tham gia vào một cộng đồng người dùng năng động.

Trải nghiệm người dùng và phản hồi từ cộng đồng

Người dùng và đối tác của xn88 thường chia sẻ câu chuyện về cách các giải pháp của thương hiệu đã giúp họ vượt qua các thách thức công nghệ và tối ưu hóa quy trình làm việc. Một vài phản hồi nổi bật cho thấy xn88 không chỉ là một công cụ mà còn là một người bạn đồng hành trong hành trình số hóa. “Trải nghiệm xn88 thực sự khác biệt ở mức độ chi tiết và dễ tiếp cận,” một quản trị viên CNTT chia sẻ. “Chúng tôi có thể thấy rõ sự cải thiện về hiệu suất và sự an tâm trong quản trị dữ liệu sau khi triển khai hệ thống.” Một quản lý dự án cho biết thêm: “Đội ngũ xn88 luôn lắng nghe, phản hồi nhanh và hỗ trợ triển khai với tinh thần chuyên nghiệp. Đánh giá xn88 từ nhóm chúng tôi thường xoay quanh sự đáng tin cậy của nền tảng và sự linh hoạt trong quá trình tích hợp với các công cụ hiện có.” Những câu chuyện như vậy cho thấy xn88 không chỉ đang bán một sản phẩm, mà đang xây dựng một cộng đồng người dùng tin cậy và đầy động lực để cùng nhau trưởng thành trong một bối cảnh số ngày càng phức tạp.

Khi người dùng tìm hiểu về xn88, họ thường tìm kiếm các từ khóa như trải nghiệm xn88 hoặc đánh giá xn88 để có cái nhìn khách quan về hiệu quả thực tế. Các nguồn phản hồi từ cộng đồng không chỉ dừng lại ở các bài đánh giá riêng lẻ mà còn được tổng hợp qua các báo cáo độc lập và các cuộc phản biện mở. Điều này cho thấy xn88 không ngại đối diện với ý kiến trái chiều và sẵn sàng cải tiến dựa trên những nhận xét mang tính xây dựng. Với sự tham gia tích cực của cộng đồng, xn88 liên tục cải tiến chất lượng sản phẩm, bổ sung tính năng và tối ưu hóa quy trình hỗ trợ, từ đó tăng cường niềm tin và mức độ hài lòng của khách hàng. Trong thế giới số đầy biến động, những phản hồi thực tế từ người dùng là nguồn lực vô giá giúp xn88 vững vàng và phát triển một cách bền vững.

Một khía cạnh khác của trải nghiệm người dùng là sự đồng hành của xn88 trong các hoạt động tương tác với cộng đồng, từ hội thảo trực tuyến, sự kiện kết nối người dùng cho đến các chương trình đào tạo và chứng chỉ về quản trị dữ liệu. Điều này tạo nên một mạng lưới người dùng và đối tác cùng chung mục tiêu: tối ưu hóa hiệu quả số hóa mà vẫn duy trì sự an toàn và tính đáng tin cậy. Người dùng nói chung đánh giá cao sự rõ ràng trong thông tin sản phẩm, khả năng tùy biến đáp ứng đúng nhu cầu thực tế của họ, và sự linh hoạt của dịch vụ chăm sóc sau bán hàng. Khi trải nghiệm xn88, người dùng có thể cảm nhận được sự chăm sóc và sự tôn trọng dành cho ý kiến của họ, điều này làm tăng sự gắn kết và khuyến khích họ tiếp tục đồng hành trên chặng đường số hóa dài hơi.

Phát triển hướng tới tương lai và tầm nhìn toàn cầu

Nhìn về tương lai, xn88 xác định một lộ trình rõ ràng nhằm mở rộng tầm ảnh hưởng và tăng cường giá trị cho khách hàng trên toàn cầu. Trong đó, ưu tiên hàng đầu là đẩy mạnh tích hợp trí tuệ nhân tạo và học máy để tối ưu hoá quy trình, mang lại hiệu quả cao hơn và trải nghiệm người dùng được cá nhân hóa. Dự án nghiên cứu và phát triển của xn88 sẽ tiếp tục tập trung vào an toàn dữ liệu, khả năng chống chịu hệ thống và sự linh hoạt trong mọi ngữ cảnh làm việc, từ văn phòng đến môi trường sản xuất và trường học. Bên cạnh đó, xn88 chú trọng phát triển các giải pháp xanh, tiết kiệm năng lượng và tối ưu hóa chi phí vận hành cho khách hàng, nhằm hiện thực hóa một kỷ nguyên số bền vững và có trách nhiệm.

Khía cạnh toàn cầu của tầm nhìn được thể hiện qua việc mở rộng mạng lưới đối tác, tăng cường sự hiện diện tại các thị trường quốc tế và thích nghi với các quy định địa phương mà vẫn duy trì chuẩn mực chung. xn88 cam kết cung cấp các dịch vụ địa phương hóa với chất lượng đồng nhất, đảm bảo rằng mọi khách hàng trên khắp thế giới đều nhận được sự hỗ trợ kịp thời và hiệu quả. Chúng tôi cũng chú trọng sự đa dạng và hòa nhập, xây dựng một cộng đồng người dùng và đối tác phong phú về nền tảng, ngôn ngữ và văn hóa, nhằm tạo nên một hệ sinh thái số thực sự toàn diện và bền vững. Với mục tiêu trở thành người tiên phong trên hành trình số hóa toàn cầu, xn88 sẽ tiếp tục đẩy mạnh đổi mới sáng tao, đồng thời giữ vững cam kết về độ tin cậy và sự tôn trọng dành cho mọi người sử dụng nền tảng của mình.

Trong bối cảnh thay đổi nhanh chóng của công nghệ và thị trường, xn88 hiểu rõ rằng tương lai không chỉ tới từ công nghệ mới, mà còn từ cách mà con người tương tác với nó. Vì vậy, chúng tôi không ngừng nâng cao kỹ năng cho đội ngũ, mở rộng mạng lưới đối tác và xây dựng các chương trình đào tạo để giúp người dùng và doanh nghiệp làm chủ công nghệ. Nhờ đó, xn88 có thể cung cấp giải pháp có hiệu quả cao, phù hợp với nhu cầu riêng, đồng thời duy trì sự an toàn và ổn định cho hệ sinh thái số mà chúng tôi xây dựng. Tầm nhìn toàn cầu của xn88 không chỉ là mở rộng phạm vi hoạt động mà còn là mở rộng cách thức mà công nghệ được dùng để cải thiện cuộc sống và công việc của mọi người.

Tóm tắt và lời mời trải nghiệm

Tóm lại, xn88 không chỉ là một thương hiệu công nghệ, mà là một đối tác đồng hành với khách hàng trên hành trình chuyển đổi số. Với nền tảng vững chắc, sự tập trung vào trải nghiệm người dùng, cam kết bảo mật và sự linh hoạt trong triển khai, xn88 mang đến một danh mục sản phẩm và dịch vụ có thể đáp ứng nhu cầu đa dạng của các tổ chức và cá nhân. Chúng tôi tự tin rằng sự kết hợp giữa công nghệ tiên tiến và văn hóa phục vụ chân thành sẽ tiếp tục tạo nên những thành công bền vững cho cộng đồng người dùng và đối tác của xn88. Nếu bạn đang tìm kiếm một trải nghiệm số đáng tin cậy, hãy trải nghiệm xn88 và tự mình trải nghiệm sự khác biệt. Để lại những nhận định và đánh giá xn88 sau khi bạn đã trải nghiệm, vì mỗi ý kiến của bạn chính là nguồn lực để chúng tôi ngày càng hoàn thiện hơn.

Hãy để xn88 đồng hành cùng bạn trên con đường khai phá tiềm năng số hóa. Dù bạn là một doanh nghiệp đang tìm kiếm phương án tối ưu hóa quy trình hay một cá nhân mong muốn giải pháp công nghệ linh hoạt cho công việc hàng ngày, xn88 luôn sẵn sàng hỗ trợ bạn. Đo lường thành công không chỉ bằng con số mà còn bằng cảm giác tin cậy và sự thoải mái khi làm việc với hệ sinh thái xn88. Chúng tôi mời bạn đến thăm quan, dùng thử và trải nghiệm xn88 ngay hôm nay, để cảm nhận sự chăm sóc và tinh thần đổi mới mà chúng tôi mang đến cho mọi người trên hành trình số hóa.

Đối Tác Uy Tin Đồng Hành Cùng XN88

XN88 bắt tay với nhiều đối tác uy tín đồng hành trong quá trình cung cấp dịch vụ cá cược online. Với các thương hiệu đình đám, chúng tôi

cam kết mang đến các tựa game hàng đầu, chất lượng đỉnh cao cùng hệ thống bảo mật tiên tiến. Cam kết mỗi phút giây trải nghiệm đều hoàn hảo.

Xn88 .locker – Tin Tức Mới Nhất

Chuyên mục Tin Tức cập nhật nhiều chủ đề hấp dẫn, từ hướng dẫn mẹo cá cược cho đến giải mã giấc mơ, giúp tân binh có những kiến thức từ cơ

bản đến nâng cao để tăng tỷ lệ thắng khi cá cược tại XN88 .