XN88 – Nhà Cái Uy Tín | Link Vào Xn88 Không Bị Chặn 09/2025

XN88 nhà cái uy tín TOP #1 thị trường Châu Á, mở thưởng cho nhiều giải đấu thể thao hàng đầu như Ngoại hạng Anh, World Cup, La Liga, Serie A, Bundesliga… FB 88 còn cung cấp nhiều trò chơi giải trí ăn khách khác gồm live casino, xổ số, bắn cá, nổ hũ, đá gà. Nhà cái có giấy phép kinh doanh hợp pháp từ PAGCOR và Cagayan, cam kết bảo mật thông tin khách hàng tuyệt đối.

xn88 - Nền tảng cược trực tuyến hàng đầu cho người chơi Việt

Trong thị trường cược trực tuyến ngày càng mở rộng, xn88 nổi lên như một nền tảng tích hợp nhiều hình thức cược từ cá cược thể thao đến casino trực tuyến và live casino. Bài viết đi sâu vào các yếu tố làm xn88 trở nên đáng tin cậy: bảo mật cập nhật, cơ chế rút tiền minh bạch, và các chương trình khuyến mãi hợp lý. Bạn sẽ được hướng dẫn cách tiếp cận một cách có trách nhiệm, nhận diện các dấu hiệu của một nền tảng hợp pháp, đồng thời khai thác tối đa lợi ích từ các sản phẩm cược.

Danh mục

Tổng quan về xn88 và thị trường cược trực tuyến

xn88 là một hệ sinh thái cược tích hợp nhiều sản phẩm, từ cược thể thao như bóng đá, tennis đến casino trực tuyến và live casino. Nền tảng này được thiết kế để tối ưu trải nghiệm người dùng với giao diện trực quan, tốc độ nạp/rút nhanh và bộ công cụ phân tích cược tiện lợi. Trong bối cảnh pháp lý ngày càng được kiểm soát chặt chẽ, người chơi nên xem xét giấy phép hoạt động, tính minh bạch của giao dịch và chính sách bảo mật dữ liệu khi đánh giá một nền tảng cược.

Đối với người chơi Việt Nam, các yếu tố đáng chú ý gồm:

- Khả năng nạp tiền và rút tiền đa dạng, tối ưu cho ngân sách cá nhân

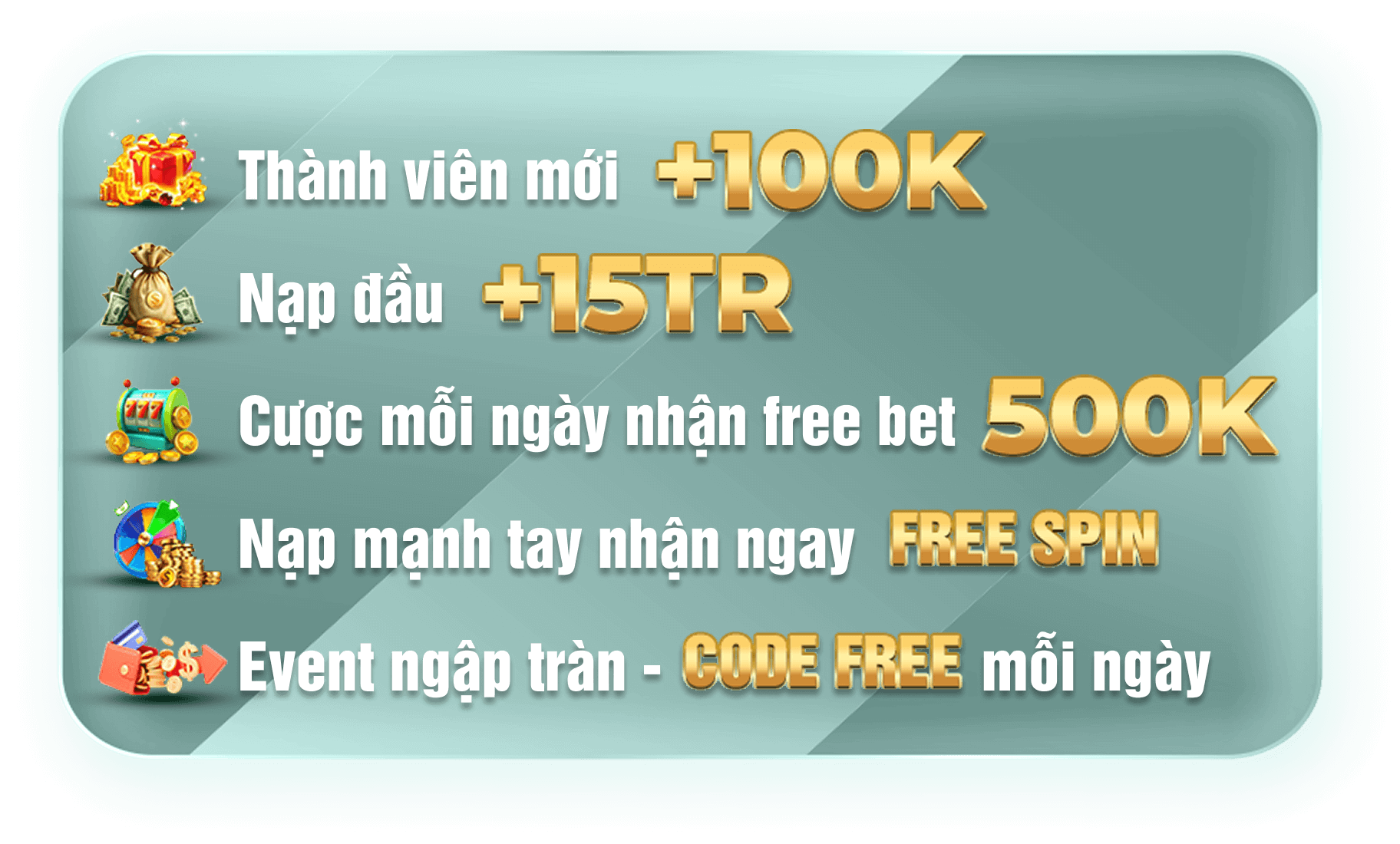

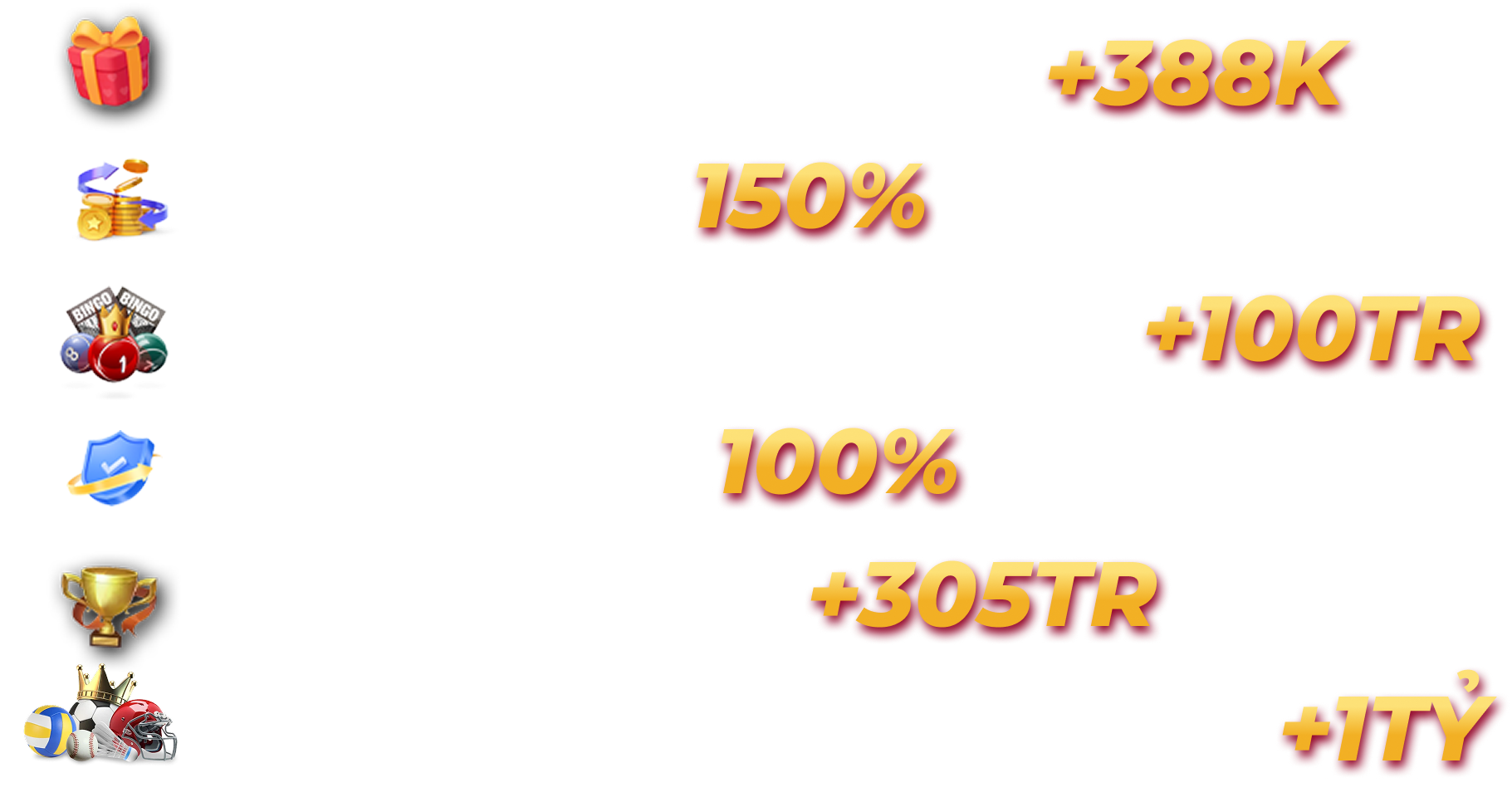

- Khuyến mãi và chương trình thưởng đi kèm điều kiện rõ ràng

- Bảo mật dữ liệu người dùng và thanh toán với chuẩn mã hóa hiện đại

- Hỗ trợ khách hàng nhanh chóng và đa ngôn ngữ

Để hình dung rõ hơn, hãy xem xn88 như một nền tảng tổng hợp: từ bảng cược thể thao cho tới sòng bạc, tất cả đều được liên kết qua một hệ thống thanh toán an toàn và quy tắc cược công khai. Bạn có thể tìm hiểu thêm về các sản phẩm bằng cách tham khảo các trang của xn88 Việt Nam, nhằm đảm bảo nhận được thông tin cập nhật nhất và phù hợp với luật pháp địa phương.

Cách chọn nền tảng cược phù hợp với bạn

Chọn một nền tảng cược không chỉ dựa trên quy mô hay phần thưởng mà còn phụ thuộc vào mức độ an toàn, tính ổn định và sự minh bạch của nền tảng đó. Dưới đây là các tiêu chí người chơi nên cân nhắc khi đánh giá xn88 hoặc các đối thủ cạnh tranh:

- Pháp lý và giấy phép: Xem kỹ các chứng nhận pháp lý, năm cấp phép và cơ chế giám sát của nền tảng.

- Bảo mật thanh toán: Hỗ trợ các phương thức thanh toán an toàn, mã hóa TLS và xác thực hai yếu tố.

- Tính thanh khoản và tốc độ rút tiền: Thời gian xử lý rút tiền và tần suất cập nhật trạng thái giao dịch.

- Giao diện người dùng và trải nghiệm di động: Tốc độ tải trang, dễ điều hướng và tối ưu trên điện thoại di động.

- Hỗ trợ khách hàng: Độ phản hồi, ngôn ngữ hỗ trợ và kênh liên hệ có sẵn.

Để người chơi dễ so sánh, có thể lấy ví dụ về phương thức thanh toán phổ biến và lịch trình xử lý tại xn88: nạp qua thẻ tín dụng, ví điện tử và chuyển khoản ngân hàng, với thời gian xử lý có thể từ vài phút đến 24 giờ tùy hình thức. Đây là yếu tố quyết định trải nghiệm người chơi lâu dài.

Để tham khảo nhanh, bạn có thể xem trang giới thiệu của đối với các thông tin cập nhật hơn về sản phẩm và điều khoản tham gia.

Chiến lược quản lý ngân sách và rủi ro

Quản lý vốn là nền tảng của cược thông minh. Đặt ngân sách cố định cho mỗi ngày hoặc mỗi tuần giúp bạn giữ vững tinh thần và tránh thua lỗ lớn do cảm xúc điều khiển. Dưới đây là một số nguyên tắc hữu ích:

- Xác định số tiền có thể mất và phân bổ cho mỗi phiên cược một cách hợp lý

- Phân bổ cược theo hệ thống, ví dụ cược theo tỷ lệ an toàn (low-risk) và bổ sung cho các tình huống đặc biệt

- Giữ kỷ luật giữ vững mức cược tối đa mỗi lần để tránh thả lỏng khi thắng hoặc thua

- Ghi chép lại mọi giao dịch và phân tích kết quả để rút ra bài học cho lần sau

Ngoài ra, bạn có thể áp dụng các công cụ quản lý rủi ro như đặt mức dừng thua (stop-loss) hoặc dừng cược khi đạt mục tiêu lợi nhuận cụ thể. Các chiến lược này giúp bạn duy trì sự cân bằng giữa niềm vui và trách nhiệm tài chính.

Hãy nhớ rằng cược nên luôn đi kèm với ý thức về trách nhiệm. Nếu bạn cảm thấy dữ liệu cá nhân hoặc tài chính bị rơi vào tình huống nguy hiểm, hãy tạm ngừng chơi và tìm kiếm sự trợ giúp từ các nguồn đáng tin cậy.

Tại sao xn88 được nhiều người chơi tin tưởng

Độ tin cậy của một nền tảng cược không chỉ dựa vào khuyến mãi hấp dẫn mà còn ở tính bền vững và sự chăm sóc cho người chơi. Dưới đây là các yếu tố được nhiều người đánh giá cao ở xn88:

- Tính minh bạch: Điều khoản cược, điều kiện thưởng và cơ chế rút tiền được công khai và cập nhật đều đặn

- Bảo mật và quyền riêng tư: Sử dụng công nghệ mã hóa hiện đại và tuân thủ chuẩn bảo vệ dữ liệu

- Hỗ trợ khách hàng: Đội ngũ tư vấn trực tuyến và tổng đài hoạt động 24/7

- Khuyến mãi có điều kiện rõ ràng: Cơ hội nhận thưởng với yêu cầu nạp ròng và vòng quay đủ hợp lệ

Khi xem xét các khía cạnh trên, người chơi Việt có thể tự tin rằng xn88 là một nền tảng có thể đồng hành lâu dài, đặc biệt khi họ chú ý tới các tiêu chí pháp lý và phản hồi từ cộng đồng người chơi khác.

Câu hỏi thường gặp (FAQ)

1. xn88 là gì?

xn88 là nền tảng cược trực tuyến tích hợp nhiều sản phẩm như cá cược thể thao, casino trực tuyến và live casino, nhằm mang lại trải nghiệm cược toàn diện cho người chơi.

2. Làm thế nào để bắt đầu cược an toàn trên xn88?

Trước khi bắt đầu, bạn nên xác minh giấy phép hoạt động, bật xác thực hai yếu tố cho tài khoản và chỉ nạp tiền bằng phương thức bạn tin tưởng. Đọc kỹ điều khoản và điều kiện thưởng, và thiết lập giới hạn cược để kiểm soát rủi ro.

3. xn88 có giấy phép hoạt động không?

Quyền truy cập và giấy phép hoạt động phụ thuộc vào khu vực pháp lý. Bạn nên tra cứu trang pháp lý hoặc liên hệ hỗ trợ để xác nhận trạng thái cấp phép hiện tại của nền tảng tại khu vực của bạn.

4. Các phương thức thanh toán được hỗ trợ?

xn88 thường hỗ trợ nhiều phương thức như thẻ tín dụng, ví điện tử và chuyển khoản ngân hàng. Mỗi phương thức có thời gian xử lý và giới hạn riêng; hãy tham khảo trang thanh toán để cập nhật chi tiết.

5. Có hỗ trợ khách hàng 24/7 không?

Các nền tảng uy tín thường cung cấp hỗ trợ qua chat trực tuyến, email và điện thoại trong thời gian 24/7. Bạn có thể liên hệ qua kênh chính thức trên trang chủ hoặc trang trợ giúp.

Đối Tác Uy Tin Đồng Hành Cùng XN88

XN88 bắt tay với nhiều đối tác uy tín đồng hành trong quá trình cung cấp dịch vụ cá cược online. Với các thương hiệu đình đám, chúng tôi

cam kết mang đến các tựa game hàng đầu, chất lượng đỉnh cao cùng hệ thống bảo mật tiên tiến. Cam kết mỗi phút giây trải nghiệm đều hoàn hảo.

Xn88 .locker – Tin Tức Mới Nhất

Chuyên mục Tin Tức cập nhật nhiều chủ đề hấp dẫn, từ hướng dẫn mẹo cá cược cho đến giải mã giấc mơ, giúp tân binh có những kiến thức từ cơ

bản đến nâng cao để tăng tỷ lệ thắng khi cá cược tại XN88 .